Search This Supplers Products:Plastic additivesRubber additivesCoating additivesPolyolefin Catalysts

Preparation and Application of Eco-Friendly Tourmaline@MOF Lignocellulose Aerogel for Fire Retardancy, Smoke Suppression, and Insulation

publisherhoey

time2024/08/16

- This study developed an eco-friendly TMLA with superior fire retardancy and thermal insulation. TMLA has lower heat and smoke emissions and minimal environmental impact.

Introduction: The Necessity of Developing Efficient Fireproof Insulation Materials

Building fires pose significant threats to human life and the environment, making the development of high-performance, fire-resistant insulation materials critically important. Lignocellulose aerogels have garnered attention as eco-friendly insulation materials due to their high specific surface area and porous structure, which contribute to effective thermal insulation. However, their flammability poses safety risks in practical applications, highlighting the importance of creating lignocellulose aerogels with excellent fire retardancy and smoke suppression properties to mitigate the catastrophic consequences of building fires.

Research Method: Combining Multiple Fire Retardant Strategies with Eco-Friendly Materials

Professor Wang Chengyu and Professor Yang Haiyue from Northeast Forestry University proposed a novel multi-fire-retardant strategy. By treating low-value wood with deep eutectic solvents (DES) and utilizing directional freeze-casting, they developed an eco-friendly tourmaline/metal-organic framework (MOF) lignocellulose aerogel (TMLA). This aerogel exhibits outstanding fire retardancy, smoke suppression, and thermal insulation. Compared to traditional lignocellulose aerogels, TMLA shows a 55.37%, 52.37%, and 64.20% reduction in heat release rate, total heat release, and total smoke production rate, respectively, with a 30.25% increase in the limiting oxygen index. Its directional structure enables superior axial insulation performance (28.13 mW/mK) and compressive strength (1.83 MPa). Additionally, life cycle assessment (LCA) results indicate TMLA's low environmental impact, making it suitable for sustainable production and application.

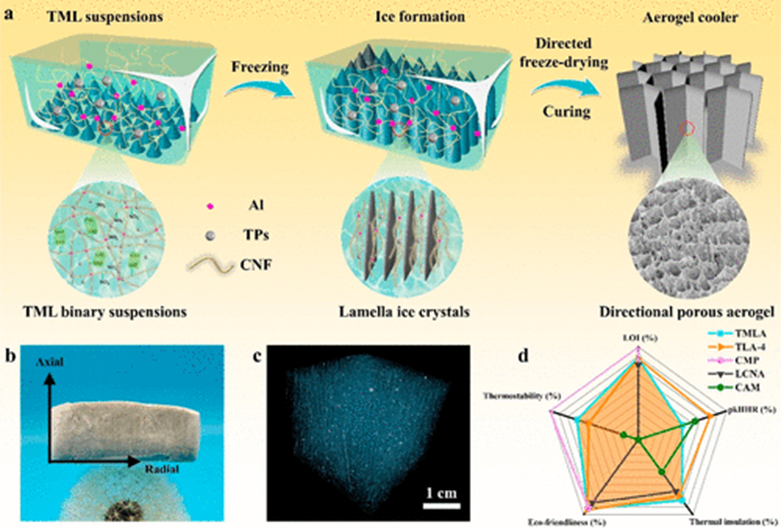

TMLA Preparation: Application of Directional Freeze-Casting and DES Treatment

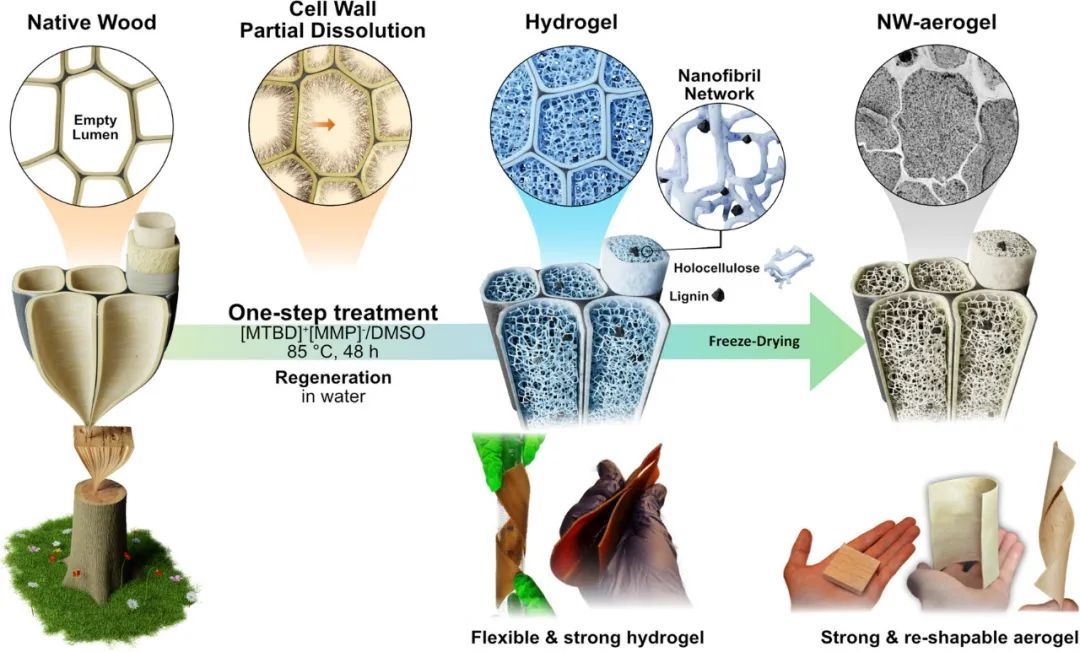

The research team employed a previously reported delignification method to reduce the lignin content in wood from 21.5% to 7.2%. They then used a DES system composed of sulfamic acid and urea to graft ammonium sulfate groups onto the lignocellulose, forming an LCNF-SO4-Al3+ complex through ion exchange. The team applied a layer-by-layer self-assembly method to synthesize MIL-53(Al) nanolayers on the LCNF surface, followed by uniform mixing with tourmaline nanoparticles (TPs). The final aerogel, TMLA, was obtained through directional freeze-drying, resulting in a material with high porosity and ultra-low density.

Microstructure Analysis: Formation and Characteristics of Vertical Channel Structures

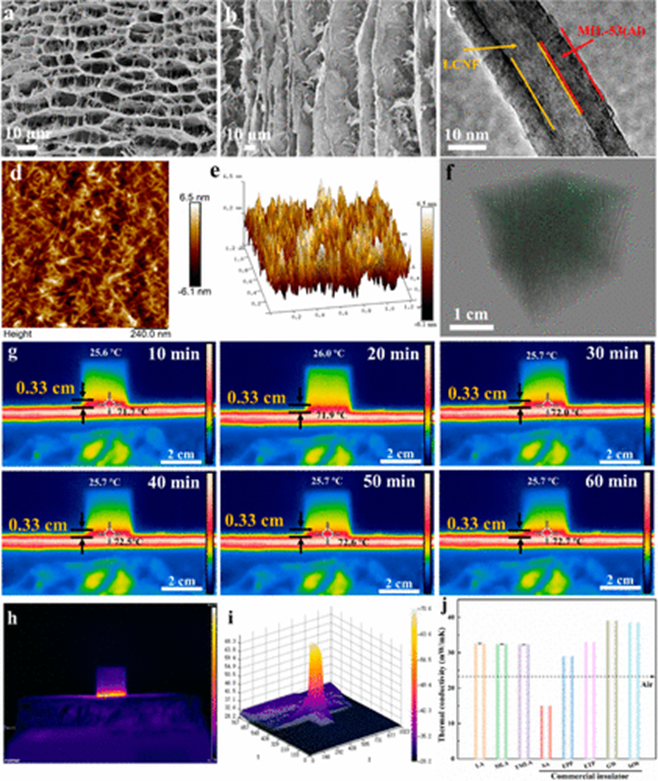

Using liquid nitrogen freeze-casting, TMLA achieved a vertical channel structure. SEM images revealed a honeycomb-like structure in the cross-section and a vertical channel structure in the longitudinal section. The self-assembly process tightly coated MIL-53(Al) onto the LCNF surface, forming a uniform nanofiber structure with TPs evenly distributed, resulting in a vertically uniform aerogel.

Thermal Insulation Performance: Superior Dimensional Stability and Low Thermal Conductivity of TMLA

TMLA, when placed on a heating plate for 60 minutes, exhibited no changes in size or appearance, indicating excellent dimensional stability. 3D thermal imaging evaluation demonstrated that TMLA outperformed other commercial materials in thermal insulation. The presence of vertical channels reduced the thermal conductivity along the ice crystal growth direction to 28.13 mW/mK, significantly lower than common commercial insulation materials.

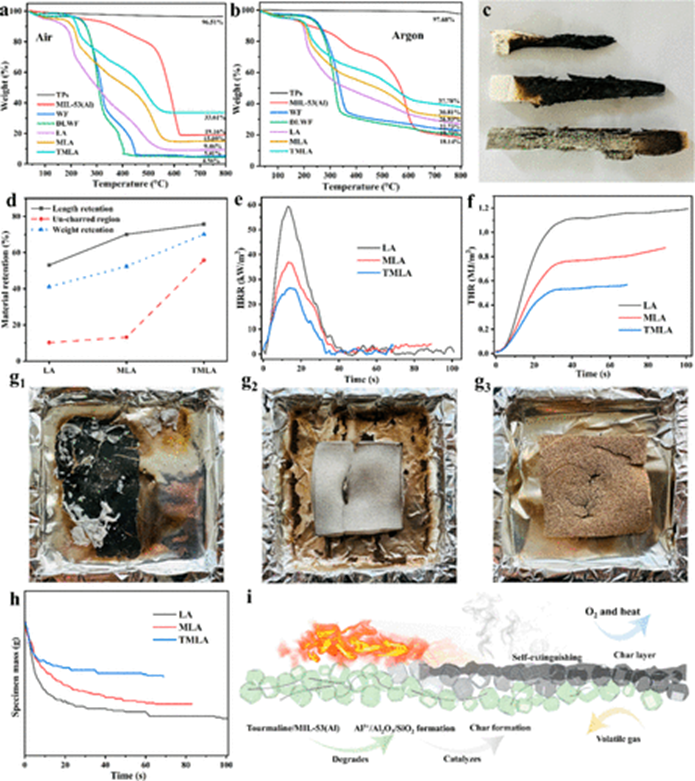

Thermal Stability and Fire Retardancy: Strong Combustion Protection Layer and Excellent Fire Resistance

The uniform distribution of TPs within TMLA formed a robust combustion protection layer, significantly enhancing thermal stability. The combination of DES treatment and the inclusion of tourmaline and MOF components resulted in substantial improvements in TMLA's fire retardancy, with a notable reduction in heat release rate, total heat release, and total smoke production. The limiting oxygen index increased, and the UL-94 fire resistance rating reached V-0.

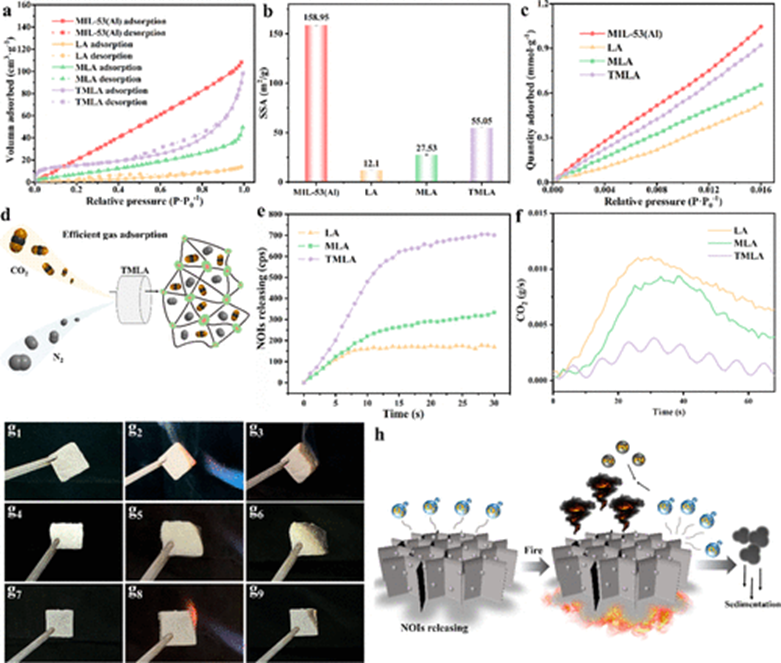

Pore Structure, Gas Adsorption Capacity, and Smoke Suppression Analysis: Smoke Suppression through Nanofiber Structures

The nanofiber structure of TMLA provided excellent gas adsorption capabilities, aiding in smoke suppression during fires. The incorporation of nanoscale TPs and MIL-53(Al) nanolayers enhanced N2 adsorption and desorption, increasing the specific surface area to 55.05 m²/g. Through a combination of respiratory effects, chemical adsorption, and micro/nanopore storage, TMLA's gas adsorption capacity was further improved, significantly reducing CO2 and total smoke emissions, demonstrating superior smoke suppression performance.

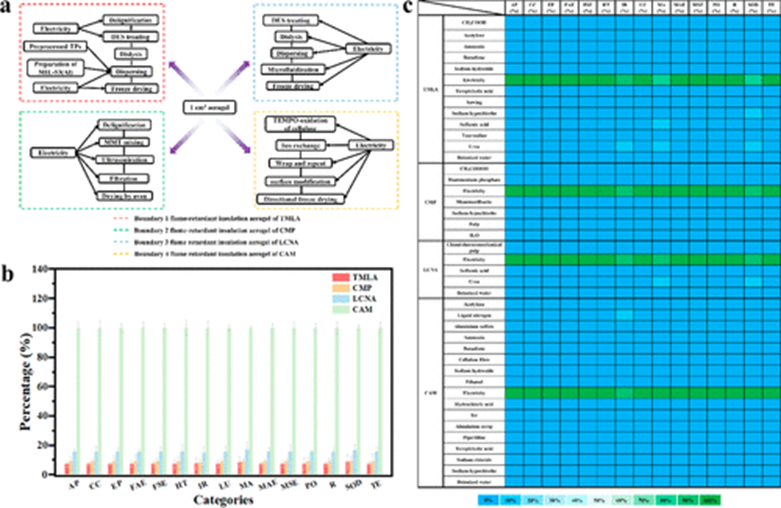

Life Cycle Assessment: Environmental Friendliness and Sustainability of TMLA

Life cycle assessment (LCA) results revealed that TMLA had the lowest environmental impact across 15 environmental categories. The green, low-toxicity, and recyclable nature of the DES method, combined with the simplicity and low energy consumption of the self-assembly process at room temperature, contributed to TMLA's low environmental footprint and sustainability.

Conclusion: A Green, High-Performance Insulation Material with Significant Application Potential

This study developed a novel self-assembled tourmaline/MIL-53(Al) lignocellulose aerogel using a green DES method and directional freeze-drying process. The resulting TMLA exhibited excellent fire retardancy, smoke suppression, and thermal insulation performance. Its porous structure and unique vertical channels contributed to a low thermal conductivity of 28.13 mW/mK. The directional freeze-drying process also enhanced the mechanical properties of the aerogel. The incorporation of ammonium sulfate, TPs, and the thermally stable MIL-53(Al) nanolayer endowed the aerogel with fire resistance. Compared to lignocellulose aerogels (LA), TMLA showed a 55.37%, 52.37%, and 64.20% reduction in HRR, THR, and TSP, respectively, with a 30.25% increase in LOI and a UL-94 fire resistance rating of V-0. Furthermore, LCA analysis confirmed TMLA's low environmental impact. Overall, this novel tourmaline/MIL-53(Al) lignocellulose aerogel is a promising energy-efficient insulation material with significant application potential in sustainable construction.